before use after use before use after use

Product Features:

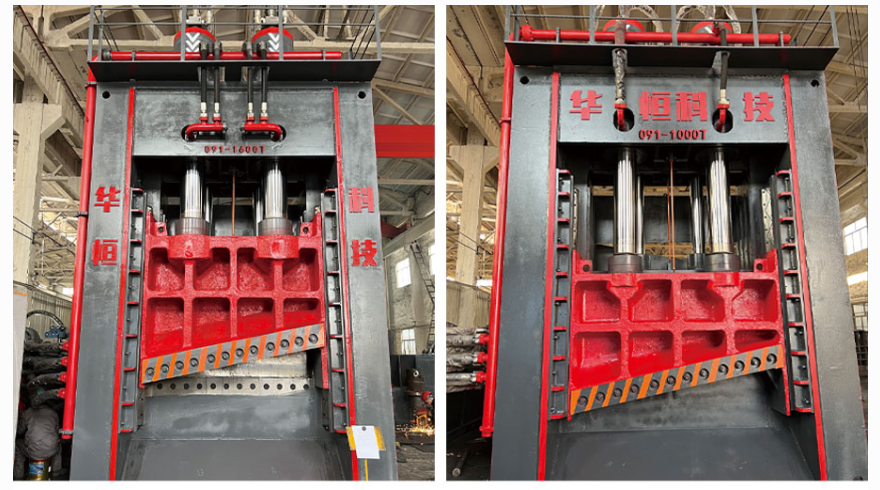

It mainly cuts various types of low-carbon, lightweight production and living scrap steel, scrapped car shells, large light metal structures made of steel, and profiles into scrap steel suitable for furnace charges. It is an ideal equipment for steel mills, non-ferrous metal smelting industries, precision casting industries, and raw material manufacturers.

Product Features:

1. The adoption of top and side compression for scrap steel shaping and segmented feeding, along with the design of a spacious material box, makes the equipment highly adaptable to various scrap steel raw materials and ensures high density after shearing.

2. The large opening area of the material box is suitable for mechanical feeding and is ideal for loose and thin scrap steel and structural steel components. It is particularly suitable for shearing pipes, plates, channel steels and other profiles.

3. It features a screen display control panel and integrated automatic control, ensuring stable and reliable operation. An optional wireless remote control device allows a single operator to control the production line equipment.

4. It is equipped with reliable high-flow logic valves, independent filtration and cooling systems, ensuring efficient and reliable system operation. The combined application of constant power variable and differential rapid technologies not only guarantees production output but also saves energy by approximately 25%, with the energy consumption per ton of steel processed being lower than the industry standard requirements.

Technical Parameters:

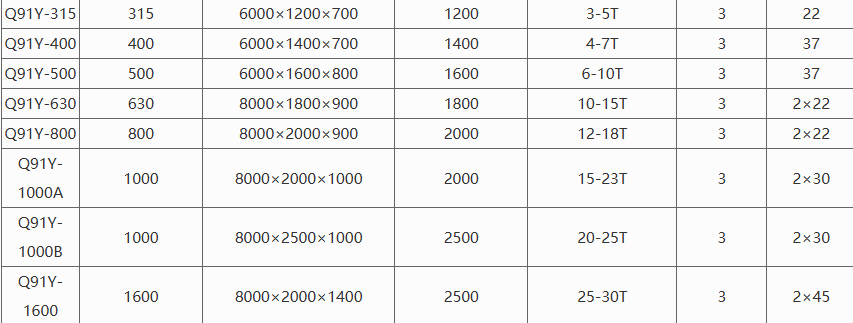

type Maximum shear force (ton) Box size of materials (L×W×H/mm) Long incision degree (mm) Output(tons/hr) Cutting frequency (times/min) Main motor power (kw)

Let’s talk about it

- WhatsAppWhatsApp:+86 19862590367

- Call UsCall Us:13914276777